Shoring is basically like giving a building or a trench temporary support when it can’t hold itself up. Simple. But in real life, it’s such an important safety step. Whether you ask what is shoring, what is shoring in building construction, or even shoring excavation, the answer always comes back to the same thing: supporting weak structures so they don’t collapse on people or on themselves.

And honestly, I love things that are practical. Construction is messy, noisy, and sometimes chaotic, so anything that keeps both people and buildings safe, I’m all for it. Plus, once you start learning the types of shoring, you realise there’s literally a method for every situation, kind of like how we all have different coping strategies in life.

Shoring in construction is used when:

- Walls crack or bulge out due to uneven settlement of the building’s foundation

- Repairs are needed to be carried out on the cracked or bulging walls

- when an adjacent building needs to be pulled down

- When openings on walls are newly created

- When already existing openings on walls are enlarged

So let’s break it down. Ready?

What is Shoring in Construction? Understand the Meaning

Shoring in construction means temporary supports that are applied to a structure or a building. A shoring system’s assembly and dismantling needs to be compliant with the decrees of Construction (Health, Safety, and Wellness) Regulations 1996. The rules made in the regulations are related to work done on buildings when there is a risk of danger or collapse to a person adjacent to or on the site.

In the Work at Height Regulations 2005, there are relevant clauses related to several risk assessments. Even though shoring is a temporary measure when more permanent supports are built, it will stay in place for a considerable time. Thus, shoring is no less significant than other elements of construction. It is to remain in place, regardless of time, and must adhere to planned safety procedures with excellent supervision during any associated assembly, and dismantling.

Why Shoring Is Needed in Construction?

Construction sites are NOT the place you want surprises. One wrong move, a slightly weak wall, loose soil, or a deep trench, and boom… things can go wrong faster. And that’s exactly where shoring quietly becomes the hero.

When people ask what is shoring in construction or what is shoring in building construction, it’s basically like giving temporary crutches to a structure that needs a little help standing. You don’t see it in the final building photos, but without it, half the construction work would literally become a safety hazard.

Especially during shoring excavation, where the soil keeps trying to fall back into the trench. Workers need that stable support so they can actually get inside and do their job without worrying about collapsing sides.

And honestly, shoring is not optional. You CAN skip it… but should you? In construction, the answer is always a big, loud, sensible no.

Now that we know why it’s needed, let’s talk about the interesting part — the actual types of shoring and when each one is used.

Different Types of Shoring Used on Site

Choosing one is not random, the site condition, soil, weather, depth, everything plays a role. Let’s break them down.

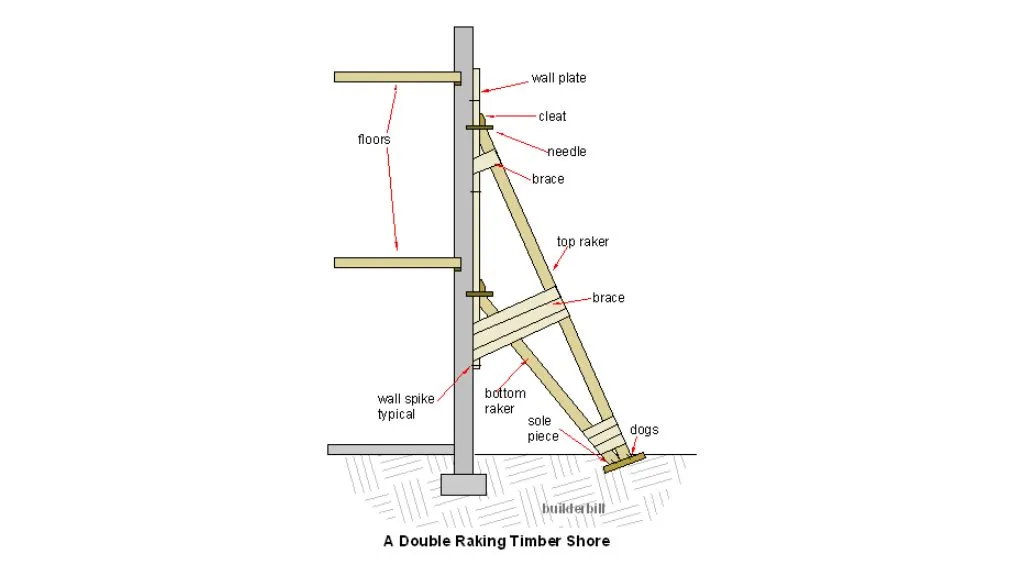

1. Raking Shoring

This one is like the strong friend who stands at an angle and holds everything together. It uses slanted supports to keep weak walls from collapsing. Mostly used for building repairs where walls are shaky. Simple, old-school, and effective.

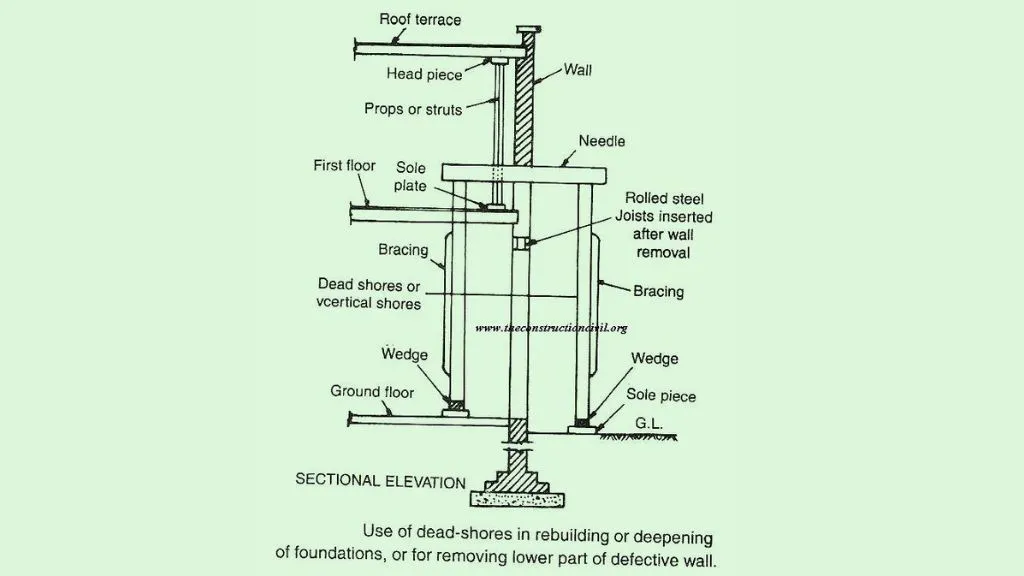

2. Dead Shoring

When you’re asking a structure to behave while you mess with its lower part (like changing columns or foundations), dead shoring steps in. It holds the load vertically.

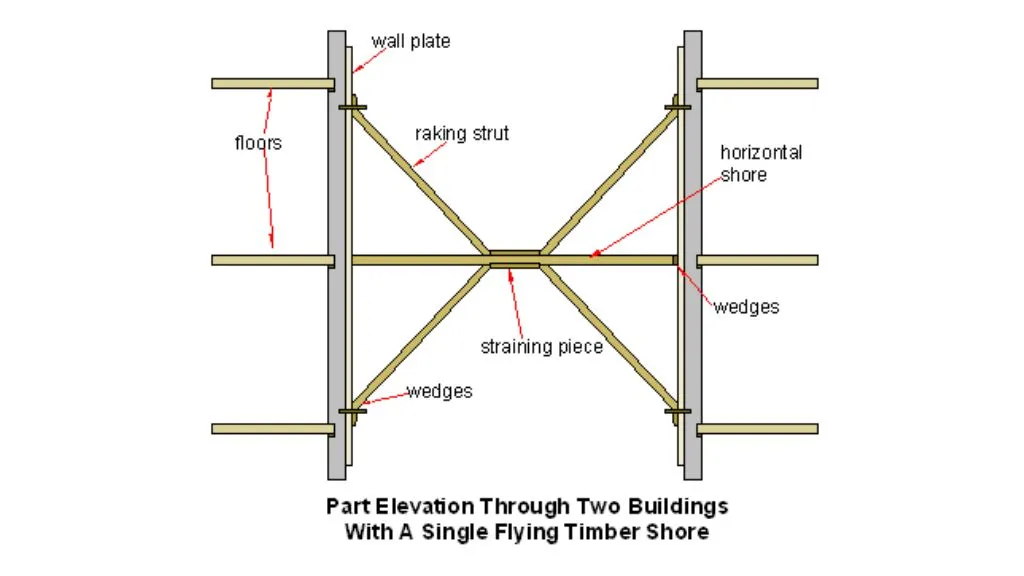

3. Flying Shoring

It supports two weak walls facing each other with a beam in between. It doesn’t even touch the ground. It literally “flies.” Great when the street is narrow and you can’t put supports below.

4. Sheet Pile Shoring

Popular in shoring excavation. Steel sheets are driven into the ground to hold the soil back. It’s messy, noisy, but super strong. Used near water areas too, because soil there is extra dramatic.

5. Soldier Pile Shoring

My personal favorite because it sounds like it has discipline. Steel H-beams are placed vertically and wooden planks fill the gaps. It’s quick and used a lot in cities where you’re digging deep.

6. Hydraulic Shoring

This is the modern, slightly expensive. Uses hydraulic pistons to push out and support trench walls. Super safe and adjustable. Many companies prefer this now because it reduces manual work.

7. Diaphragm Walls

These are permanent. Huge concrete walls built deep into the ground before excavation even starts. Expensive but extremely strong. Used for basements, metros, high-rise buildings… basically anything big and complicated.

There are more types of shoring, but these are the ones you’ll come across the most. Each one solves a different problem , because no two construction sites behave the same. And that’s the beauty of it.

How Shoring Works: Step-by-Step on a Construction Site

If you’ve ever stood at a construction site, even for five minutes, you’ll know one thing: nothing goes as “smooth” as those YouTube tutorials show. Shoring is the same. It looks simple on paper, but on site… oh ho, it’s a whole story.

First thing the engineers do is figure out why shoring is needed. Is a wall weak? Are we digging a deep foundation? Is the soil behaving like loose sand from the beach? Once that’s clear, they pick the right method. That’s where all the types of shoring we spoke about come in.

Then the team marks the area and starts setting up supports. In shoring excavation, this step is literally life-saving. Because soil collapses don’t give a warning . They just happen. So workers place the shoring frames, sheets, or beams before removing too much soil. (I’ve seen sites where they dig first and shore later… let me tell you, everyone’s heartbeat stays in their throat until the support goes in.)

Once the shoring is installed, the real work begins. Digging, repairing, constructing, whatever the project demands. While this is going on, engineers keep checking if the structure is stable. If the soil shifts, or a support becomes loose, or rainwater creates drama, adjustments are made immediately.

And finally, when the main work is done and the structure is strong enough to stand on its own, the shoring is removed. Slowly. Carefully.

Shoring might look like a temporary thing, but the role it plays is anything but small. It literally buys time and safety for everything else to happen.

Shoring for Walls & Weak Structures

Shoring isn’t just for digging, it’s also used to support walls, beams, and other structures temporarily. Wooden or steel props are placed against walls or under beams to hold them steady while construction or repair happens. Engineers carefully plan the placement so weight is distributed safely. Without it, even small vibrations from machinery could cause cracks or collapses.

Basically, shoring for walls is like giving a building a temporary backbone until it can stand strong on its own again.

Shoring for Excavation & Deep Foundations

Whenever you dig deep for foundations or basements, the surrounding soil can cave in. That’s where shoring steps in to keep the trench or pit safe.

Timber, steel, or hydraulic supports are used to brace the sides.

So, whenever you hear “shoring excavation”, think of it as temporary armor for your digging project. Safe and secure, until the concrete or structure takes over.

Main Benefits of Shoring in Building Construction

Shoring isn’t just about holding stuff up, it actually makes construction safer, faster, and more efficient. First off, it prevents collapses during excavation or while erecting walls. Workers could move freely without worrying about sudden accidents.

It also supports weak structures, allowing renovations or extensions without tearing everything down. And, honestly, it reduces repair costs later since there’s less risk of structural damage during construction.

So, when someone asks “what is shoring in building construction”,: it’s your temporary hero, holding, bracing, and keeping the site safe while the real structure takes shape.

Conclusion: Why Shoring Is Essential for Safety

So, that’s the lowdown on shoring in construction—basically, it’s the unsung hero that keeps everything from collapsing while workers are busy digging, building, or expanding. From simple vertical supports to complex needle and flying shoring, each type plays a crucial role in keeping a site safe and stable.

Whether it’s a small shoring excavation for your home extension or a massive commercial project, knowing what is shoring in building construction and which types of shoring to use can save time, money, and a lot of headaches. So next time you walk past a construction site and see all those props and beams, you’ll know, there’s a whole system working silently to keep everything standing.

If you’re thinking about your own construction project, remember: safety first, plan well, and let shoring do its magic!

What is Shoring in Construction FAQs:

1. What is the purpose of shoring in construction?

Honestly, shoring is a way to support walls, trenches, or structures temporarily while work is going on. Think of it like crutches for a building.

2. Why do we need shoring in building construction?

Without shoring, soil or walls can collapse. It’s mainly about safety, for workers, for materials, and for the structure itself.

3. What are the types of shoring used in construction?

There are quite a few! Some common ones are timber shoring, steel shoring, raking shoring, and needle shoring. Each is used depending on the site and project needs.

4. What is shoring excavation?

Shoring excavation is basically supporting the sides of a trench or pit while digging. It’s a lifesaver.

5. Can shoring be used for both small and big projects?

Absolutely! From home basements to multi-storey buildings, shoring adjusts to the scale. You just pick the right type for the job.