Property Geek

We provide the actual and accurate information with unbiased user driven reviews to our viewers, to help them see the best and find the best!

View posts

Cement is a versatile and essential material in the world of construction, known for its ability to bring together and solidify different elements. It is the binding agent that creates the strong foundation upon which many structures are built.

Cement is used in concrete, a harmonious combination of aggregates such as gravel and sand, bound together by the cohesion of water and cement. The construction industry in India recognizes various types of cement to suit the unique requirements of each project, taking into consideration factors such as the soil, climate, and the desired outcome of the structure. Each type of cement serves a specific purpose and is carefully chosen to ensure the longevity and stability of the finished product.

With this let’s take a closer look at different types of Cement in India:

Before we delve deeper into different types of cement, here’s a list of different types of cement recognized by the American Society for Testing and Materials (ASTM):

OPC (Ordinary Portland Cement) is the most commonly used cement for all types of construction. It is also the most widely used and produced type of cement in the world with an annual global production of 3.8 million cubic meters each year.

Rapid hardening cement is used in concrete when formworks are to be removed at an early stage. Thereby, the cost of construction can be reduced while the rate of construction increases. It is similar to OPC with increased lime content, finer grinding, and higher c3s content.

However, it has higher strength development than OPC. the strength of rapid hardening cement at 3 days is similar to the strength of OPC at 7 days even with the same cement-water ratio. This type of cement is used in the construction of roads, prefabricated concrete, etc.

You might think, from the name, that rapid hardening cement and quick-setting cement are quite similar but no. This type of cement is used in construction under running or static water.

This type of cement reduces the risk of concrete coming in contact with sulfates. This is also the reason they are widely used in the construction of foundations as the soil has high sulfate content. C4AF and C3A are less in this type of cement.

Sulfate resisting cement finds itself in rampant use for constructions that might get exposed to sulfate action by soil and water such as in siphons, retaining walls, culverts, canal linings, etc.

This type of cement is produced by grinding clinkers with 60% slag. The properties of blast furnace slag cement more or less resemble the properties of Portland cement. It is used widely in places where there is an economic consideration.

High alumina cement is produced by melting a mixture of lime and bauxite and mixing them with clinkers. It is a type of rapid hardening cement with a final and initial setting times of 5 and 3.5 hours respectively.

The comprehensive strength of high alumina cement is quite high and more workable than OPC. It is used in concretes that have to face acidic action, frost, and high temperatures.

White cement, a type of ordinary portland cement, is prepared from raw materials of iron oxide. It is white and is costlier than ordinary types of cement in India. They find themselves in profound use for architectural purposes such as terrazzo surfaces, facing panels, precast curtain walls, etc.

There are several other uses of white cement such as building,

Coloured cement is produced by taking a mixture of 5% to 10% mineral pigments and ordinary cement. They are widely used in decorative work on floors.

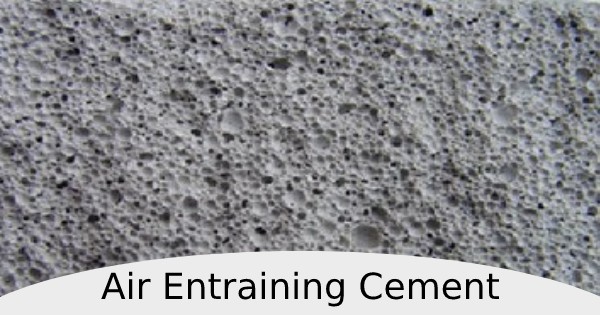

Air entraining cement is obtained by mixing indigenous air-entraining agents such as sodium salts of sulfates, glues, resins, etc. with clinkers. Both the materials are ground together to get air-entraining cement.

This type of cement is perfectly suitable for improving the workability with smaller cement to water ratio. It also improves the frost resistance of concrete.

This type of cement expands slightly over time and will not shrink during or after its time of hardening. Expansive cement is specifically used for prestressed concrete ducts and grouting anchor bolts.

This type of cement is obtained by mixing several water-repelling chemicals. It has high strength and workability. Because of the property of repelling water, it stays unaffected during the rains or monsoon.

Hydrographic cement finds major use in the construction of water structures such as water retaining structures, spillways, water tanks, dams, etc.

Concrete and cement are terms often used interchangeably but actually cement is an ingredient in concrete. Cement is a mixture of tricalcium silicate, dicalcium silicate, tricalcium aluminate, and tetra-calcium aluminoferrite. It takes around 24 hours to 48 hours after the initial set for cement to dry after which forms can be removed and people can walk on it. The surface becomes okay for vehicles to drive over after 7 days of partial curing. It takes about a month for a concrete structure to be fully cured.

OPC is generally considered the best type of cement used for construction in India. OPC 53 is the typical grade used for constructing all RCC structures such as slabs, beams, columns, and footing. Wherever the structure requires initial and ultimate strength OPC 53 is used.

SRC stands for Sulphate Resistant Cement and it is a type of blended cement that improves the performance of concrete in case of a sulfate attack. SRC also provides increased durability for concrete in extremely aggressive environments and reduces the risk of the structure deteriorating.

GGBS stands for Regen Ground Granulated Blast furnace Slag. It is a substitute for cement manufactured from a by-product of the iron-manufacturing industry. A tonne of Regen in concrete will reduce CO2 embodiment by around 900kg. It also provides improved stability.

Cement is the binding material that adheres to other materials so it can never be used alone. It is a component of both mortar and concrete as well as thin-set adhesive, tile grout, and stucco.

Concrete consists of 4 primary ingredients:

The more the amount of water in the concrete is, the more brittle it will be. Water is what activates cement in concrete to act as an adhering agent.

There are 13 types of cement in India: