Simran

Simran is a passionate writer and has two cute little pets. With a home that is filled with books and the smell of freshly brewed coffee, she is on the steps of adding more content for everyone to read and ponder.

View posts

Achieving the perfect mix in construction is crucial for ensuring durability, strength, and stability. However, selecting the right type and mix ratio can be confusing, especially with varying requirements for concrete, mortar, or plaster.

Using incorrect proportions may compromise the structure’s integrity, leading to costly repairs or failures. In this article, we break down the different types of construction mixes and provide easy-to-follow mix ratio tables, helping you make informed decisions for your building projects with confidence and precision.

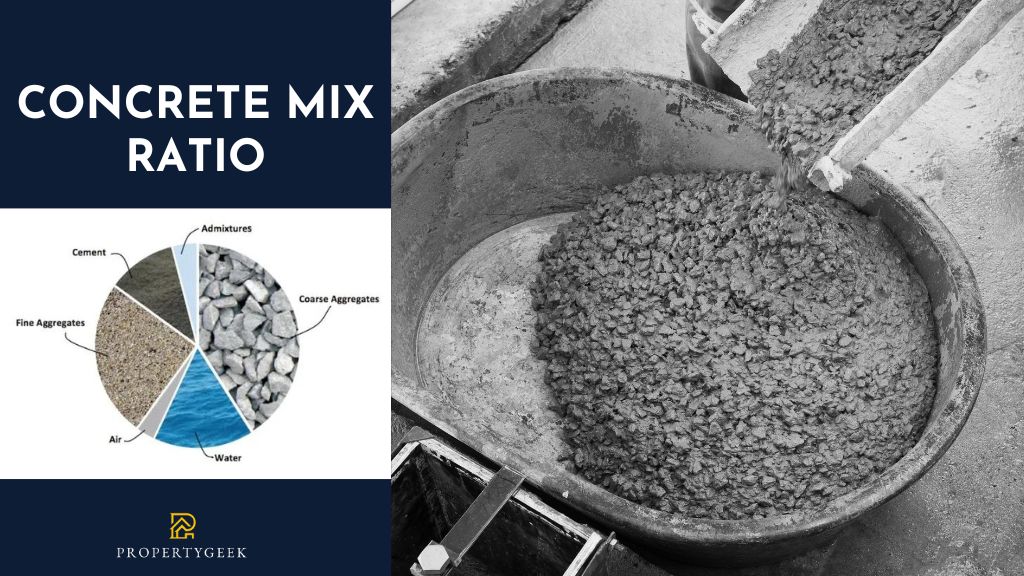

The ratio of concrete mix is defined as the proportion of the components that make concrete such as water, aggregates, sand, and cement. How do we determine what ratio is to be used? IS 456-2000 has designated concrete mixes into grades such as M40, M35, M30, etc. here. M refers to the mix and the digit refers to the strength of the mix after its 28th day in N/㎟.

Check out these different types of concrete mix ratio and their grades:

The mix design of high-strength concrete depends on the properties of w/c ratio, sand aggregates, and cement which must be above 40 MPa. It must have a low w/c ratio to obtain high workability and proper compaction. For compressive strength values for each grade refer to the table given below.

|

Sl. No. |

High Strength Concrete Grade |

Mix Ratio |

Compressive Strength | |

|

Mpa (N/㎟) |

psi | |||

|

1 |

M50 Concrete Mix Ratio |

Design Mix |

50 |

7250 |

|

2 |

M55 Concrete Mix Ratio |

Design Mix |

55 |

7975 |

|

3 |

M60 Concrete Mix Ratio |

Design Mix |

60 |

8700 |

|

4 |

M65 Concrete Mix Ratio |

Design Mix |

65 |

9425 |

|

5 |

M70 Concrete Mix Ratio |

Design Mix |

70 |

10150 |

In this type of concrete mix, the ratio of ingredients is mentioned by the producer while the performance of the concrete is mentioned by the designer. However, the minimum cement content is laid down. This type of mix ratio is economical and is a rational approach. There are several factors that determine the strength of the mix in a designed concrete such as

The specification of making concrete meant prescribed proportions of cement and coarse and fine aggregates which ensure adequate strength to the mix. These are termed nominal mixes and under normal circumstances, they have a margin of strength that is above the specified value. However, its workability varies significantly because of the variability of its ingredients. Here’s a table showing the mix ratio and compressive strength of different grades of nominal concrete:

|

Sl. No. |

Nominal Concrete Grade |

Mix Ratio |

Compressive Strength | |

|

MPa (N/㎟) |

psi | |||

|

1 |

M5 Concrete Mix Ratio |

1:5:10 |

5 |

725 |

|

2 |

M7.5 Concrete Mix Ratio |

1:4:8 |

7.5 |

1087 |

|

3 |

M10 Concrete Mix Ratio |

1:3:6 |

10 |

1450 |

|

4 |

M15 Concrete Mix Ratio |

1:2:4 |

15 |

2175 |

|

5 |

M20 Concrete Mix Ratio |

1:1.5:3 |

20 |

2900 |

The nominal mixes of cement and aggregate vary widely in strength and might over or under-rich the mixes. This led to the code specifying the minimum compressive strength for concrete mixes called the standard mix ratio. IS 456-2000 specified concrete mix ratio to grades M40, M35, M30, M20, M15, and M10. Check out the table below to know more!

|

Sl. No. |

Standard Concrete Grade |

Mix Ratio |

Compressive Strength | |

|

Mpa (N/㎟) |

psi | |||

|

1 |

M25 Concrete Mix Ratio |

1:1:2 |

25 |

3625 |

|

2 |

M30 Concrete Mix Ratio |

Design Mix |

30 |

4350 |

|

3 |

M35 Concrete Mix Ratio |

Design Mix |

35 |

5075 |

|

4 |

M40 Concrete Mix Ratio |

Design Mix |

40 |

5800 |

|

5 |

M45 Concrete Mix Ratio |

Design Mix |

45 |

6525 |

Concrete mixing needs to meet certain proportioning and selection factors concerning its ingredients. They must satisfy the following requirements: