Property Geek

We provide the actual and accurate information with unbiased user driven reviews to our viewers, to help them see the best and find the best!

View posts

It’s important to know which kind of concrete is best for a construction job because there are many different kinds. The “slump” of the concrete should be taken into consideration too. Continue reading to learn more about this material, how it affects your work, and the different types of slumps.

Concrete’s “slump” is the consistency of fresh concrete before it sets; the slump is proportional to how fluid the concrete is. Even though it sounds like a complicated procedure, it is quite straightforward when it comes down to it.

Although the term “slump” is typically used to describe the act of sinking or slouching, it is quite appropriate for concrete because it is measured by determining how much a pile of concrete sinks when left to stand. A sample of the concrete is placed in a cone, the cone is removed, and the distance the concrete has sunk is measured.

The slump test is a standard method used to determine the workability of concrete in construction projects. It involves filling the cone-shaped tool with freshly mixed concrete, compacting it with a standard rod, and then lifting the cone of the concrete to see how much it slumps or settles.

The amount of slump is measured in inches or millimetres and indicates the level of workability of the concrete mixture. A higher slump value indicates a more fluid and workable mixture, while a lower slump value indicates a stiffer and less workable mixture.

The appropriate slump value for a particular concrete mix depends on various factors such as the type of construction project, the type of concrete used, and the placement and finishing methods used. Contractors and engineers use slump tests to ensure that the concrete mix meets the desired specifications and can be placed and finished according to the project requirements.

Based on its average slump value, a concrete slump is classified into one of five classes, S1 through S5, as shown in the grid below. Concrete in class S1 is a moderately dry blend, and it gets more liquid when you go further up the classes.

|

Class |

Slump range |

Target slump |

|

S1 |

10 – 40 |

20 |

|

S2 |

50 – 90 |

70 |

|

S3 |

100 – 150 |

130 |

|

S4 |

160 – 210 |

180 |

|

S5 |

210 – 220 |

220 |

S1 concretes are preferred for bedding curbs and other pipework, S2 for hard-standing slabs and strip footings, and S3 for trench-filled foundations requiring high flowability, according to consensus.

Due to their typically specialized applications, such as slabs, pumping/piling concrete, and foundation, concretes in the S4 and S5 classes necessitate the assistance of an experienced concrete technologist.

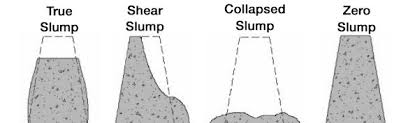

The nature of the concrete sink can be used to classify the slump in concrete. The slump comes in four varieties. They are

Here the concrete simply subsides quickly in a true slump and retains the mould’s shape. Slumps of this kind are highly desired. The only reliable condition for determining concrete’s workability is the true slump. The test should be repeated if additional types of slumps are found.

A shear slump occurs when one-half of the cone slides down in an inclined plane. Shear slump indicates that the concrete mix lacks cohesion. When a harsh mix is used, a shear slump may form.

In this instance, fresh concrete completely collapses.

Assuming cement keeps up with the genuine state of the form, it is called zero slumps which address firm, predictable, and practically no functionality.

Concrete slump is a term used to describe the consistency and workability of freshly mixed concrete. It refers to the degree of fluidity or stiffness of the concrete mixture, which is measured in terms of its deformation under the weight of a standard cone-shaped tool known as a slump cone.

In summary, the concrete slump is a crucial aspect of concrete workability that determines how easily the mixture can be placed, compacted, and finished in construction projects.

Slump measures and demonstrates the fluidity, consistency, and workability of freshly mixed concrete. Simply put, the more the mix is wet the higher the slump will be formed. With normal-weight concrete, a four-inch slump is common and advantageous for pumping.

The consistency of fresh concrete is measured using the concrete slump test before it sets. It is carried out to examine the workability of newly produced concrete and, consequently, the ease with which it flows. It can also be used to identify a batch that has been mixed incorrectly.

The binary mixes had slump values of 126 and 147 mm for concretes of grade M20 that were higher than those of the controlled mix.

Place a straight edge across the base of the slump mould, preferably the tamping rod, with one end suspended above the concrete pile. Measure the distance between the displaced centre of the slumped concrete and the bottom of the straight edge with a ruler or tape. Keep track of your findings to the nearest quarter of an inch.

A higher slump, otherwise known as a flowing concrete blend are affordable ready-to-mix products with high flowability with zero comprise in its strength. High-range water-reducing admixtures (superplasticizers) are used to achieve these high slumps and their high-strength properties.

One method for determining a mix’s suitability and quality is through a concrete slump test, which ensures that the water-to-cement ratio is correct. A concrete slump test will likewise give the chance to recognize any defects and correct them before the concrete is mixed.

The slump value (in millimetres) of the concrete used in typical RCC work for beams, slabs, and other structures is specified in IS 456-2000. is 50 to 100 mm. Low-workable concrete is best for concrete work.

The suitable type of slump for most hand-placed flatwork is 5.5 inches. For chunks hit off with mechanical hardware, it’s two to four millimetres.

Except if generally allowed or indicated, the concrete ought to be proportioned and created to have a downturn of 4 inches or less on the off chance that it’s to be combined by vibration. The slump should be no more than 5 inches if it is consolidated in any other way.

Most specifications allow concrete slump to vary around 1 inch. Reject it if the slump is more than 112 inches from the order.