Property Geek

We provide the actual and accurate information with unbiased user driven reviews to our viewers, to help them see the best and find the best!

View posts

Compressors are one of the essential elements in industrial sites as they offer easy support to heavy-duty operations. It is necessary to choose the most appropriate Type of Air Compressor to provide a useful source of electricity for the tools.

The types of compressor refers to a machine used in industries to convert one type of energy into another that can be stored and eventually used later. Different types of Air compressors are powered using diesel, gas engines, and electric motors.

Given that they may be utilized as a power source for electric tools, air compressors are some of the most essential equipment found at construction sites. There are several varieties of air compressors, each with certain advantages and disadvantages.

Based on their internal processes, air compressors can be classified as positive displacement or dynamic displacement. The four most typical types of air compressors are as follows:

Below, we’ll go through the main characteristics of each kind and describe how each one functions to help you make an informed selection for your project.

Classification of compression Depending on the types of compression, may be positive displacement or dynamic displacement.

Nonetheless, in the industrial sectors, some of the most common types of compressors that are used include the following:

This type of compressor can generate power using air displacement. These air compressors have different internal working mechanisms, but the working principle remains the same for almost all compressors.

The compressor has a cavity responsible for holding air carried from outside. The cavity in the machine responsible for storing is brought from outside which is then compressed to increase the potential energy and air pressure.

Reciprocating compressors are one of the most popular types of displacement compressors. These compressors are mostly used in small work sites such as home construction or garage.

These might not be eligible for working continuously, however, their moving parts are usually more numerous and are thoroughly lubricated by the use of oil to ensure proper movement. This is why most domestic refrigerators make use of reciprocating compressors.

These types of air compressors have a piston within the cylinder that is responsible for compressing and displacing air for building pressure. Unlike other compressors- these are usually available in different variations such as multi-stage and single-stage.

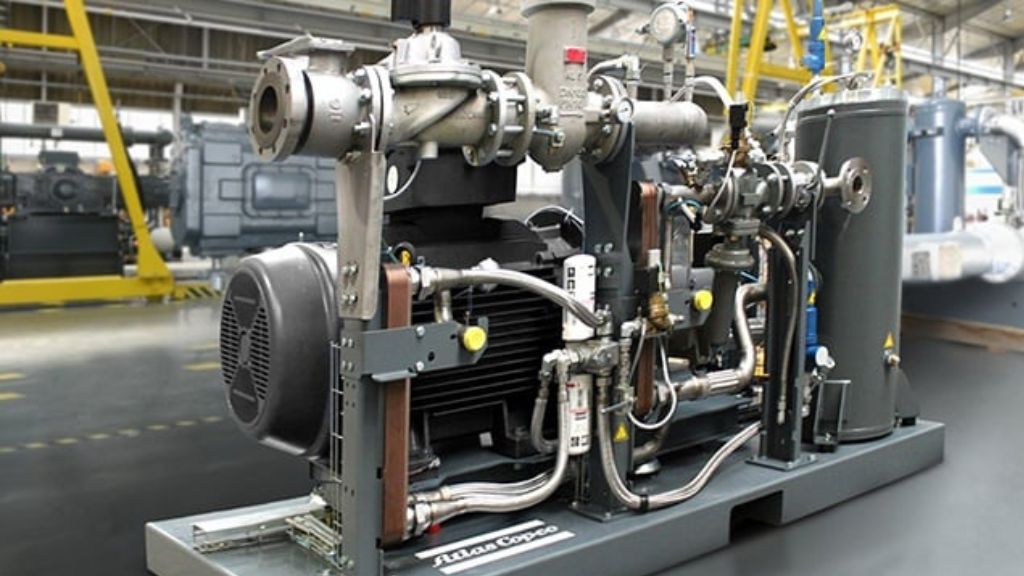

Rotary screw compressors are one of the most commonly used compressors because they don’t require extensive maintenance and have an internal cooling system.

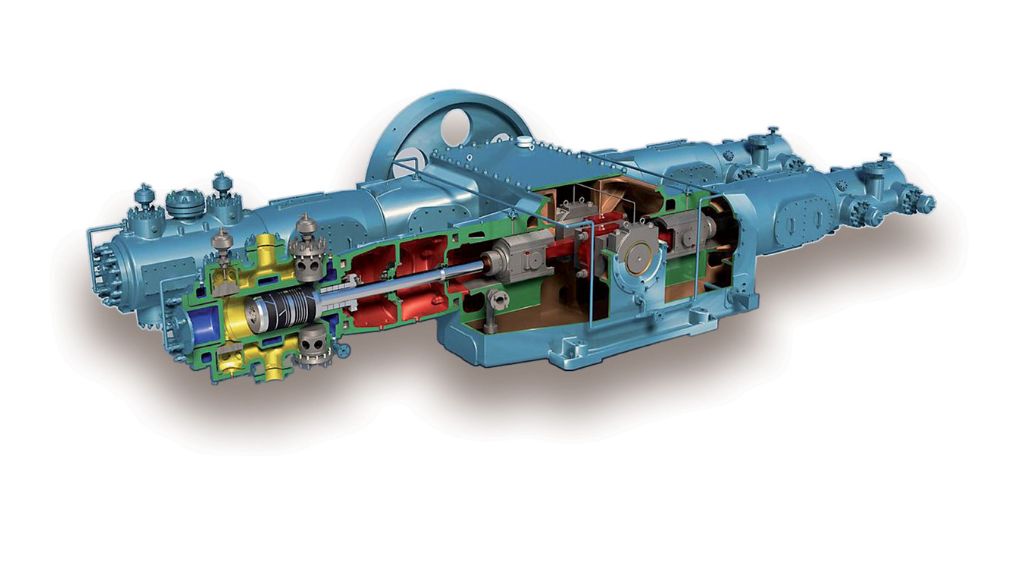

The rotary screw types of compressors are large compressors that can either run oil-free or be lubricated using oil. The compressors have two internal rotors responsible for generating energy within these. The pressure builds up when the air gets trapped between the opposing rotors.

It features an internal cooling system that can function within a range of 5 horsepower to 350 horsepower.

The rotary screw compressors are further divided into two types of screws:

The dynamic compressors are further of two types- axial and centrifugal. These types of compressors are responsible for generating horsepower as they draw air into the fast-rotating blades and then restrict the airflow to generate pressure. The kinetic energy is stored in a static form in a dynamic air compressor.

Fixed-speed compressors run at a specific speed that can operate completely when the motor is in a running phase and the air is being compressed. However, it may become inefficient if the unit unloads. After a certain point, the compressor will spot functioning.

On the other, a variable-speed compressor can help turn the motor into a specific amount of air. The speed of the motor usually depends on the demand of the device. In a variable-speed compressor, there is significantly less chance of energy wastage.

Whenever using these types of compressors, it is advisable to conduct an air usage audit. The audit will play an essential role in understanding the energy consumption by each of these.

different types of Air compressors are power-generating machines that can be extremely handy in the long run. These can help to determine the energy output level. However, if you are purchasing these for industrial purposes, you will need to consider the following:

Whenever you choose oil-free compressors, you need to check the air quality. The oil-powered air compressors may not be handy if the compressor is being purchased for a clean manufacturing environment.

The air compressors mostly use oil for lubrication, creating fumes and contaminating the air, thereby hampering the entire manufacturing process. However, using an oil-free compressor in the manufacturing environment can help to reduce the risk.

Comparatively, the oil-free compressors are expensive, but they offer proper cleaning. A small amount of oil will be helpful for machine lubrication. The running cost for oil-free compressors is usually low because the parts do not require constant maintenance.

Long construction projects require energy efficiency, and it is necessary to use energy-efficient compressors that can be worthwhile in the long run. Natural gas compressors can be effective for functioning with different equipment and tools.

These tend to run more efficiently than others and easily manage the partial load. Comparatively, the natural gas air compressors can function more efficiently even with partial loads. The heat recovery capabilities of the same are usually higher than the electric compressors.

If you need to move the compressor across different sites, you must choose a portable compressor. There are small and lightweight units that are available in compact packaging.

These compact units aren’t as powerful as large units and can only be efficient for small projects. These units can also be plugged within the car adapter to use an airbrush painting or tire inflation tool.

Many air compressors are available in the market with extra features. You need to determine whether you need these or not. Most air compressors feature thermal protection to determine the internal heating and prevent motor damage. Many air compressors also sport a belt-drive system that can be efficient for quiet operation.

The types of compressors are used for responsible for pumping refrigerant from the refrigeration system and every other kind has its own control system. Therefore, before purchasing one, you must determine whether you need it for a small-scale or large-scale project. Additionally, it is also advisable to check the airflow of the same.

The article above provides a thorough guide on types of compressors and how to choose one. To get the maximum value for money, you must make sure to check the small detator to make the purchase a vital one.