Bricks are the most basic yet important materials used for building construction in India. They have been used since ancient times due to their low cost and durability. Due to modern techniques, however, bricks found today are more refined, strong, and durable. There are different types of bricks used in construction depending on the material, size, and texture. There are several advantages of using bricks for construction:

- Cost-efficient

- Easily available

- Highly customizable

- Eco-friendly

- Simple installation

What are The Advantages and Disadvantages of Using Brick in Construction?

Bricks are the most important building material, and the majority of construction relies on them. These days, the kinds of bricks that are used to build buildings have become more sophisticated, have better strength and stability, and are cheaper.

Let’s check out its advantages and disadvantages in construction:

Advantages

- Brick is a material that lasts a long time and is durable.

- It is resistant to fire and can withstand high temperatures.

- For environmental protection, brick does not require the use of paints.

- Problems with individual bricks can be fixed without having to tear the structure down and start over.

- Bricks can be made locally with the help of readily available clay, reducing shipping costs. This may indicate that brick construction may be less expensive than construction with stone, concrete, or steel.

Disadvantages

- Constructing takes a long time.

- Bricks readily absorb water, which may result in a lack of airflow and break under high seismic pressure.

- It is challenging work to clean brick surfaces.

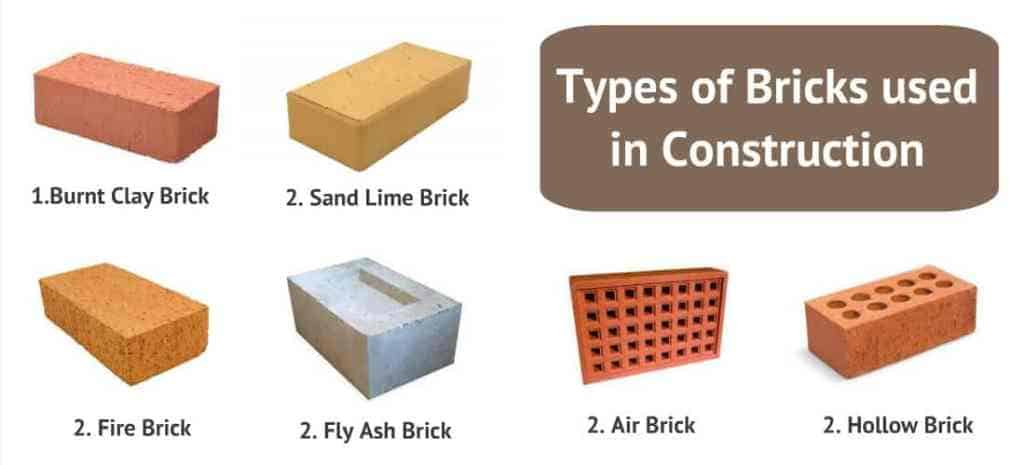

Types of Bricks Used For Construction In India

The following are the most popular types of bricks used in Indian construction:

1. Sun-dried or Unburnt Clay Bricks

The creation of these bricks involves the preparation of clay, moulding, and finally drying moulded bricks under sunlight. These bricks are not suitable for permanent structures as they lack strength and are not fire or water-resistant.

2. Burnt Clay Bricks

These clay bricks are burnt under fire and are further categorized as :

● First Class Brick

These standard-sized bricks are of better quality when compared to second-class bricks. They are well burnt in large kilns and table molded. They are uniformly deep red in color. They are free from any kind of cracks, lumps, flaws, chips, or efflorescence. It is also free of any pebble, gravel, and organic matter. When two first-class bricks are struck against each other, they must produce a clear ringing sound. They are recommended for constructing permanent structures. They are however costlier than the rest because of superior build quality.

● Second Class Brick

Second-class bricks are ground-molded and burnt in kilns. They are light red in color and are not as refined and uniform as first-class bricks. There are a small number of cracks and distortions present. They have a slightly rough surface. They produce a metallic sound when struck against each other. It is used in the construction of temporary sheds or single-storied buildings.

● Third Class Brick

Third class bricks are irregularly shaped and sized. They are light red-colored. The texture is non-uniform and the brick is under-burnt. They are riddled with cracks and distortions. When struck against each other, they emit a dull sound. These are used for temporary structures and are not advisable for use in rainy areas.

● Fourth Class Brick

These are extremely low-quality bricks, which are crushed and used in the manufacturing of concrete. They are over-burnt and as a result, are brittle in nature, which makes them unsuitable for construction activities. Although, they are widely used in road construction, floors, and foundations as a coarse aggregate material.

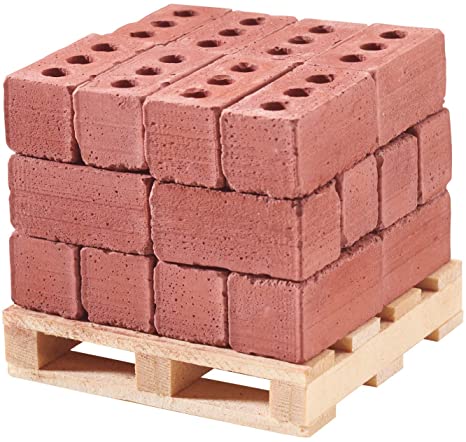

3. Concrete Bricks

Concrete bricks are made up of cement, sand, coarse aggregates, and water. They can be customized as per requirements at the manufacturing level. They can be manufactured at the construction site, thereby optimizing resources. There are 2 types of concrete bricks depending on shape, dimensions, and structure. They are:

Solid Concrete Blocks

Heavy and manufactured from dense aggregate, solid concrete blocks are significantly strong, thus able to provide robust structural support and stability. They are easy and consume less time to manufacture.

Hollow Concrete Blocks

These types of bricks are hollow inside, and depending upon the utility, can be manufactured into different shapes and sizes. These lightweight blocks may have several hollow compartments as per requirements.

There are different types of hollow concrete blocks, such as

- Bullnose blocks

- Stretcher blocks

- Jamb blocks

- Corner blocks

- Pillar blocks

- Partition blocks

- Lintel blocks

- Frogged brick blocks

You can refer here to understand the previously mentioned hollow blocks.

4. Fly Ash Bricks

These bricks are manufactured using fly ash and clay. The fly ash is obtained as a by-product when burning coal mixed with water, which is then fired at 1000 degrees Celsius. Rich in calcium, these bricks are used for the construction of pillars, walls, and foundations. The fly ash c is a versatile material and most sought after in construction as it has high strength and better fire insulation than the rest. It is available in uniform sizes which enables better joints. It also has lower water penetration. These bricks are self-cementing and do not require plastering. It consumes the least water when compared with other conventional materials.

5. Jhama Bricks

These bricks are fired at a high temperature for a longer duration compared to other bricks. As a result, they are also known as ‘vitrified bricks’ or overburnt bricks. Jhama bricks are often used in slab and beam construction using concrete or at places where there is little to no water encountered.

6. Engineering Bricks

These bricks have high compressive strength and low water absorption. Wherever strength, low water porosity, and acid (flue gas) resistance is needed, engineering bricks are used. Engineering bricks are used for damp-proof courses and basement construction, basically, areas that are prone to high water or acid encounter.

7. Sand Lime or Calcium Silicate Bricks

These bricks are manufactured using sand and lime. Calcium silicate bricks are cost-friendly and provide superior heat, water, and noise resistance. They are widely used across the globe and have uniform colour and texture. Ornamental works in buildings extensively use calcium silicate bricks. On the other hand, due to their delicate nature, these bricks are avoided for laying foundations, building furnaces, and paving.

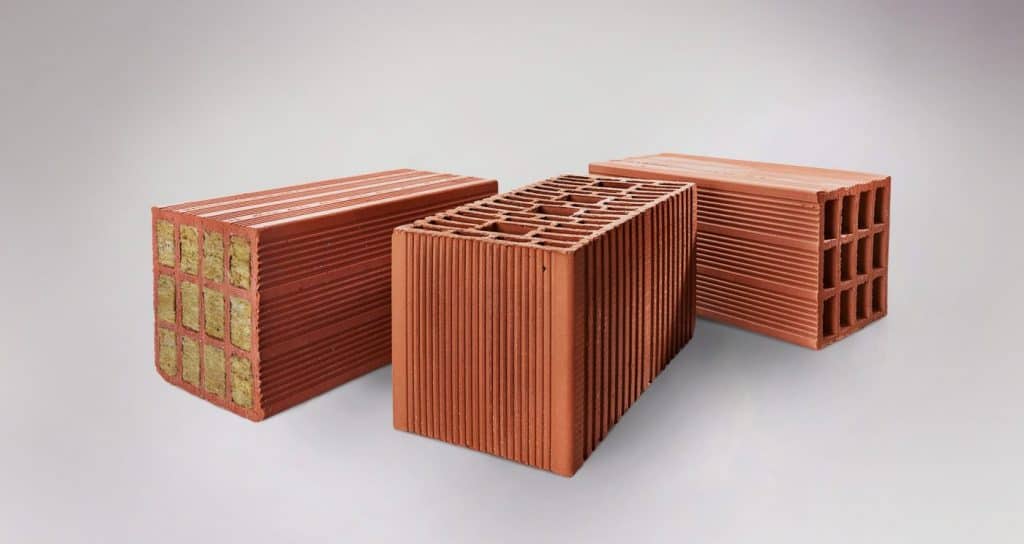

8. Porotherm Smart Bricks

These are perforated hollow types of bricks, which are either vertically or horizontally perforated. Porotherm smart bricks are manufactured using toxic-free natural materials, and being hollow from the inside makes them more efficient than solid traditional bricks.

These bricks are lightweight, cost-effective, and eco-friendly. They also provide thermal and acoustic insulation. It consumes far less water when compared to other bricks, and takes less time for curing too. Many urban companies are using these bricks to reduce environmental impact and ensure safe and stable structures.

9. Fire Bricks

These bricks have extremely high fire resistance. Also known as refractory bricks, fire bricks, as the name suggests, are extensively used for the lining of chimneys, furnaces, and ovens, where the temperature is very high. These are widely found in the construction of structures in rural and dry areas.

10. Facing Bricks

Aesthetically pleasing types of bricks which are used on the exterior of the wall, usually at the principal front of the property are called facing bricks. Facing bricks are available in different styles, colours, and textures. As they form the exterior surface, they are manufactured to be maintenance-free, weather-resistant, and provide thermal insulation.

11. Paving Bricks

Paver means thin, flat bricks used in paving projects such as walkways, driveways, and patios. They are either made of clay or concrete. Paving bricks are long-lasting, cost-efficient, and require less maintenance.

Final Thoughts

To sum it up, bricks are a cost-efficient replacement for stones used in construction. There are different types of brick made up of natural and synthetic raw materials. Whether it is for foundation or decoration, indoor or outdoor, structural or pathways; for every need, there are several types of brick manufactured to help create, repair or strengthen the infrastructure built. They provide protection from heat, water, and even weather-related adversities, plus look stylish and elegant. They are highly customizable for individual use and are highly cost-efficient. The installation of bricks is simple, unlike other materials.

Different Types of Bricks FAQs :

1. What to watch out for while selecting bricks ?

While selecting bricks for construction activity:

2. What is the most common type of bricks used in Indian constructions ?

Even today, clay-based bricks are the most commonly used in Indian construction

3. What is the difference between concrete and clay bricks ?

There are 3 major differences between concrete and clay bricks:

4. Which type of paver brick is recommended for home driveways ?

Since clay-based paver bricks are long-lasting, available in different colors, and look elegant, they are recommended for home driveways. They are also eco-friendly and require less maintenance.

5. Which type of brick is paint-friendly ?

As clay-based bricks emit metallic salts which cause the paint to peel off faster, concrete-based bricks are considered paint-friendly.

6. When compared, which material is cheaper for construction: stone, steel, or clay ?

As clay bricks are locally manufactured, eliminating costs related to logistics and storage, it is cheaper than stone and steel.*LAT PULL-DOWN MISTAKES*